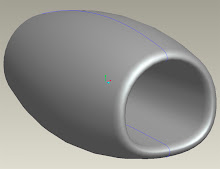

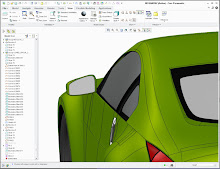

Sram: The industrial designers at Sram, makers of Grip Shift and Rockshoks, have always used Rhino and Alias to make product to hand over to Engineers to either import or remodel. Now with Pro/ENGINEER training their industrial designers can work on engineering models and offer engineering a 3D Pro/E deliverable. Since Sram's engineers took the same class they now know how to manage any modifications to the model as they see fit. The industrial designer can now manage ribs on the front forks as ribs are visible to the consumer they should be handled directly by industrial designer and not necessarily the engineers. Industrial designers using Pro/ENGINEER instead of Rhino saved 30 hours per product and streamlined the process so engineers don't have to be tied to the static IGES data.

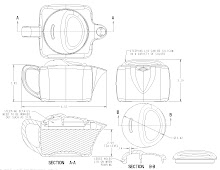

Rubbermaid: From one engineers' new found skills for "proving form" the engineer can make live modifications on the screen in front of CEO and other engineering managers saving weeks of revision circles.

Knoll: After taking Surfacing training at design engine Knoll engineers can now create more accurate lead times.

General Atomics: After taking the surfacing week long intensive, they don't have to hire outside consultants to handle the complex surfacing of their Aero forms.

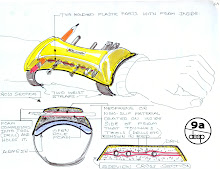

Nike: Nike sent industrial designers and engineers together in the week long surfacing class, where they both discovered a unique work flow of capturing form and proving form. This cut 40 hours out of their design process. This forty hours saved six weeks lead-time for one specific product to hit the market.

Fisher-Price: After some Fisher Price Engineers took a surfacing week, their entire design process changed, work flow from conception to production. Because Industrial designer and engineers both took the class together, they worked together to formulate a written process that enabled industrial designer to maintain control to a specif point and passed off the development to engineering at another point. The engineers can take a Rhino or Alias model and reformulate the design using Pro/ENGINEER with a new process. The collective team shaved off 19 weeks out of a 10 month design to tooling process.

Grayhill: An engineer from Grayhill stated that his new skills with Pro/ENGINEER and surfacing (Johnathan is a degree d industrial designer taking the specific seven day class to ID'ers) helped foster a collaborative environment where he can now work on engineering models more efficiently. Reinforced brand identity through all involved parties speaking the same mathematical language.

Call Design Engine today to speak to a instructor about our surfacing class

312.226.8339

Tuesday, January 12, 2010

Surfacing Training at Design Engine: How did they benefit?

Labels:

engineering,

industrial design,

pro/engineer,

proe training,

rhino,

surfacing

Subscribe to:

Posts (Atom)